At BioVitamine, special attention is given to quality assurance and quality control. BioVitamine sets the highest standards in terms of reproducible process controls and, of course, consistent compliance with GMP guidelines. Regular tests before, during and after the production processes guarantee a constant high quality. The works have several laboratories equipped with state-of-the-art analytical instruments and outstandingly well trained specialist personnel.

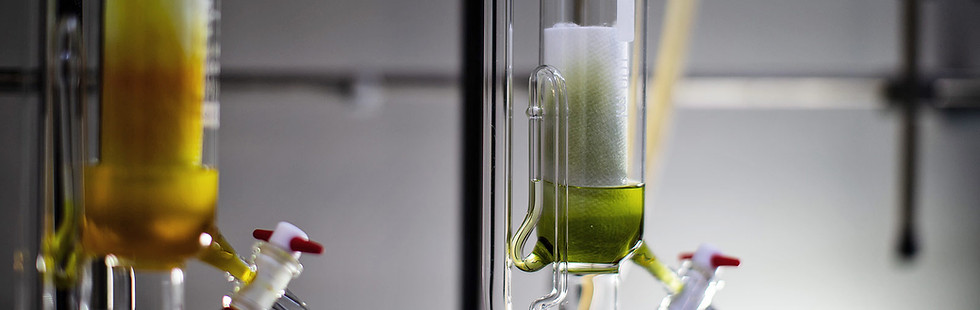

Transparent process chains, from cultivation of plants right through to the end product, are the foundation of continuous quality at all stages. Freshly harvested plants and drugs (dried medicinal plants) are processed without exception in our own production sites. After thorough checking upon delivery, these controlled raw materials are processed using gentle methods. Advanced technological development means a great deal to us. Production is manifestly state-of-the-art and can therefore satisfy the extremely high quality requirements of industrial customers as well as the needs of drugstores and pharmacists for high quality specialities. An example of our state-of-the-art technology is the percolation system. BioVitamine employs a four-stage system for this extraction process, which guarantees highly concentrated extracts with reproducible process control.

State-of-the-art infrastructure and supreme demands on chemical engineering pave the way for reproducible process management. The quality control includes defined in-process controls and final lab analyses. The production stages comply with cGMP guidelines.

All employees are regularly trained and have the appropriate education and training for the manufacture of herbal products. BioVitamine produces in compliance with the WHO (GACP), PIC (cGMP), Swissmedic and IMO guidelines in terms of the area of bio-extracts.

With state-of-the-art equipment at every production stage, BioVitamine’s quality control safeguards the quality requirements according to currently valid pharmacopoeias (HAB, DAB, Ph. Helv., Ph. Eur.) and food guidelines. As regards quality, we are a reliable partner for our customers, from production to quality assurance. cGLP as well as validated methods according to ICH guidelines are standard at BioVitamine..

DEVELOPMENT AS CORE COMPETENCE

Quality Assurance as a Basis

Purely Extracted, Rigorously Tested

Very promising projects in research & development as well as a great deal of successful launches of our own developments are the result of many years of specific work. Our specialists closely collaborate with an international network of various different universities and colleges. These scientific joint ventures guarantee constant innovation and improvement in the area of our products and services.